|

L-body Rod Shifter Adjustment Procedure

For Proper Reverse Lockout Operation

Put the transmission in neutral.

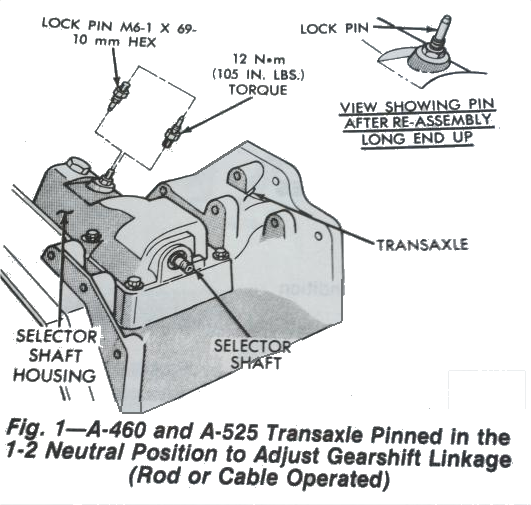

STEP 1: Working over the left fender you may need to remove the air cleaner housing to gain access to the transmission locking pin which is threaded into a hole that is located on the top of the selector shaft housing as shown in Figure 1 below.

STEP 2: Remove the pin and flip it over and re-insert it into the hole while pushing in on the slector shaft. A hole in the selector shaft rod will allow you to insert the pin fully and then tighten it down gently. This step locks the shifter position for the selector shaft in the 1/2 neutral position.

STEP 3: Raise the car on a hoist or (emergency brake engaged...safety first.) put the front of the car on appropriate jack stands. Do not do this with the car raised with just a scissors jack. The car must be firmly supported for safety.

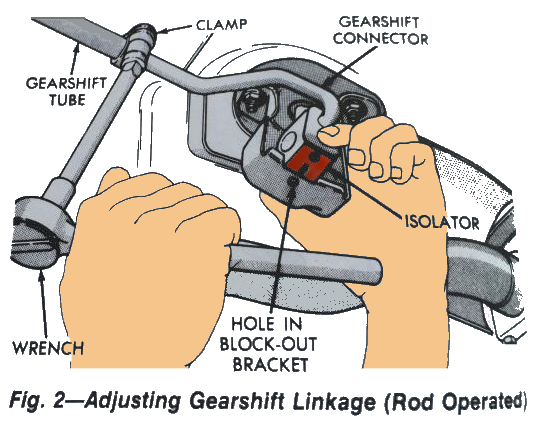

STEP 4: Get a 13mm box wrench or deep 13 socket and ratchet. Loosen the nut on the shifter end of the long shift tube and confirm that the adjustment shaft can be moved fore/aft and that it also can turn left or right for the needed adjustment. If there is no flat washer under the nut, install one for a better clamping force and to prevent damage to the pinch strap.

Adjusting the linkage:

STEP 5: Set the rod such that the rivet on the movable shifter portion of the assembly, the rivet that holds on the reverse lockout pad, is aligned with the hole in the shifter bracket sub assembly. It is approximately in the middle of the assembly and should be easy to identify. See figure 2 below.

STEP 6: Then move the yoke of the shifter portion of the rod with the small riveted pad of the reverse lockout till it is flush with the bracket then tighten the bolt.

STEP 7: Remove the pin from the selector shaft housing and test the shift. If you can still hit reverse w/o pushing down, or if you can't get reverse at all, there is likely a problem with the lever pin on top of the differential bracket. This pin has a history of coming loose and making the shift rod assembly loose. The pin can not be ‘tightened’ it has to be welded back to a solid position. If the pin is not loose, check that the bolt on the selector shaft bracket is tight. If the shift is working properly, reinstall the shift selector shaft housing locking pin in the reverse (up) position.

NOTE

The shift rods have plastic ends on them and they get old, tired and worn out. Sometimes they just pop off, sometimes the larger ones get loose and sloppy and the previous owner or automotive technician may have adjusted the linkage to compensate. You will serve yourself well by replacing them with a turbododgeparts.com l-body quick-fit, race-ready or street-n-strip shift linkage assembly. Either of these ready to install assemblies replace the plastic ends with a quick disconnect ball and socket or heim/spherical bearing rod end for a GREATLY improved shift and they will last forever! These are not kits, they are completely upgraded assemblies that you exchange your old parts for.

If you don’t have a lot of tools like taps and dies, a good drill press and a high-speed die grinder, forget about trying to hunt down the parts needed to fabricate your own shift rod upgrade and doing the upgrade yourself. We have done this many times and have a complete shop so even with that, it's not so easy as you might think or you have been told. For example, the small selector shaft bracket on the transmission selector shaft is (very) hardened steel, you need a high speed die grinder and bit or a tungsten stepper bit for that part as well as a good vice and work bench. The rest of the levers are mild steel and you can just drill them out as needed for the bolts and studs. You would also need a good quality tap and die set to create threads on the ends of the shift rods where the plastic ends would be removed.

All that being said, the shifter upgrade is perhaps some of the best $$ you will spend and you'll never have to worry about shift linkage problems again, and they are completely adjustable as needed. There is little in life more aggravating than to have a shift rod pop off at a traffic light or in a parking lot on a hot or cold day and not having the time or the tools to #DealWithIt. Trust us...we know 1st hand!

|