|

Many people come to the point where they are forced to change the spark plugs on their vehicle and face a difficult decision; copper spark plugs or those of another type? You can find spark plugs in a variety of different metal combinations, including aluminum spark plugs, iridium plugs, platinum and more.

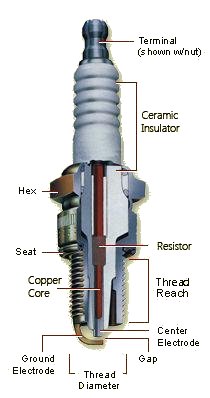

Terminal Post: One-piece terminal post adds strength.

Multi-Ribbed Insulator: Reduces the danger of “flash-over” - an electrical spark between the metal shell and the terminal, which would cause the engine to misfire. Such an external spark obviously means there is no spark at the electrodes.

RFI Resistor: Many spark plugs contain radio frequency suppressors to reduce ignition noise that can sometimes be heard on the vehicle’s radio.

Center Electrode: Full copper core center electrode provides optimal performance in all conditions.

Hex (Steel Shell): The cold-formed steel shell is manufactured with precision rolled threads for a secure fit, and easy installation and removal. In addition, the spark plug’s shell must provide an electrical ground to the cylinder head, and help cool the plug by transferring heat to the head.

Ground Strap Electrode: Also called the side electrode, it is made of high-nickel chromium alloy.

Purpose of the Metal

The metal in a spark plug serves a single basic purpose: to channel the electric energy from the plug wire through the spark plug so that it can be forced to the engine block in the form of a spark. Therefore, any metal that conducts electricity at all could potentially be used for a spark plug. The metal should also not get too hot; one of the main problems with some metals is that they overheat quickly, causing the electric charge itself to be compromised and the spark plug to not operate as smoothly.

Copper Spark Plugs

Copper spark plugs are generally considered to have the best performance of any spark plug type. This is potentially different from what advertising companies suggest, but the other metals are, unfortunately, not as conductive in general as copper is. Platinum and iridium plugs are more likely to overheat, which causes damage to the plug components and can compromise the delivery of the spark to the engine block.

Platinum and Iridium Plugs

Platinum and Iridium plugs perform at a lower level than copper spark plugs, because they are less conductive and they tend to overheat. However, the overall longevity of these two types of metal is better than copper plugs.

In reality, copper has the best performance of all three and the worst longevity. Platinum has good longevity and the worst performance. Iridium has good longevity and a performance that is decent, which is why iridium plugs tend to be more expensive than any other type. Still, the difference between these plugs in terms of overall quality is minimal, as there is a trade off for each.

Most copper plugs need to be changed every 20,000 miles or so. Platinum and iridium plugs can often go for twice that before they require changing, but the overall performance will not be as good and you may have to deal with overheating of the plugs. This is the reason that it is common to run a slightly 'colder' platinum or iridium plug in an engine that was spec'd with a copper plug from the factory. This is potentially not worth the added cost of both platinum and iridium spark plugs, although the decision will depend upon your preference, service interval and cost of service.

Copper core spark plugs are still the most commonly seen, however, and many people agree that they are the best. However, the advertising that accompanies the different types of spark plugs is potentially misleading, so it's important to recognize the real difference between the spark plugs in question. In order to do that, it's necessary to first learn about what the metal in the spark plug is used for.

Spark Plug Heat Range

The operating temperature of a spark plug is the actual physical temperature at the tip of the spark plug within the running engine. This is important because it determines the efficiency of plug self-cleaning and is determined by a number of factors, but primarily the actual temperature within the combustion chamber.

There is no direct relationship between the actual operating temperature of the spark plug and spark voltage. However, the level of torque currently being produced by the engine will strongly influence spark plug operating temperature because the maximum temperature and pressure occurs when the engine is operating near peak torque output (torque and RPM directly determine the power output). The temperature of the insulator responds to the thermal conditions it is exposed to in the combustion chamber but not vice versa.

If the tip of the spark plug is too hot it can cause pre-ignition or sometimes detonation/knocking and damage may occur. If it is too cold, electrically conductive deposits may form on the insulator causing a loss of spark energy or the actual shorting-out of the spark current.

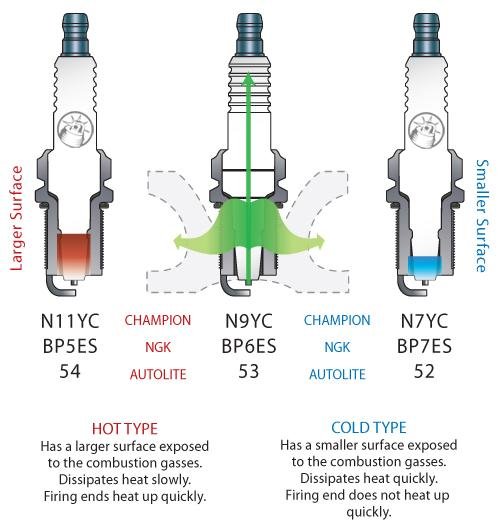

A spark plug is said to be "hot" if it is a better heat insulator, keeping more heat in the tip of the spark plug. A spark plug is said to be "cold" if it can conduct more heat out of the spark plug tip and lower the tip's temperature. Whether a spark plug is "hot" or "cold" is known as the heat range of the spark plug. The heat range of a spark plug is typically specified as a number, with some manufacturers using ascending numbers for hotter plugs and others doing the opposite, using ascending numbers for colder plugs.

The heat range of a spark plug is affected by the construction of the spark plug: the types of materials used, the length of insulator and the surface area of the plug exposed within the combustion chamber. For normal use, the selection of a spark plug heat range is a balance between keeping the tip hot enough at idle to prevent fouling and cold enough at maximum power to prevent pre-ignition or engine knocking. By examining "hotter" and "cooler" spark plugs of the same manufacturer side by side, the principle involved can be very clearly seen; the cooler plugs have a more substantial ceramic insulator filling the gap between the center electrode and the shell, effectively allowing more heat to be carried off by the shell, while the hotter plugs have less ceramic material, so that the tip is more isolated from the body of the plug and retains heat better.

Heat from the combustion chamber escapes through the exhaust gases, the side walls of the cylinder and the spark plug itself. The heat range of a spark plug has only a minute effect on combustion chamber and overall engine temperature. A cold plug will not materially cool down an engine's running temperature. (Too hot of a plug may, however, indirectly lead to a runaway pre-ignition condition that can increase engine temperature.) Rather, the main effect of a "hot" or "cold" plug is to affect the temperature of the tip of the spark plug.

It was common before the modern era of computerized fuel injection to specify at least a couple of different heat ranges for plugs for an automobile engine; a hotter plug for cars which were mostly driven slowly around the city, and a colder plug for sustained high speed highway use. This practice has, however, largely become obsolete now that cars' fuel/air mixtures and cylinder temperatures are maintained within a narrow range, for purposes of limiting emissions. Racing engines, however, still benefit from picking a proper plug heat range. Very old racing engines will sometimes have two sets of plugs, one just for starting and another to be installed for driving once the engine is warmed up.

The heat range must be carefully selected for proper spark plug thermal performance. If the heat range is not optimal, then serious trouble can be the result. The optimal firing end temperature is approximately between 500°C (932°F) and 800°C (1472°F). The two most common causes of spark plug problems are carbon fouling (< 450°C) and overheating (> 800°C).

Spark Plug Heat Dissapation

The term heat range refers to the speed with which a plug can transfer heat from the combustion chamber to the engine head. Whether the plug is to be installed in a boat, lawnmower or race car, it has been found the optimum combustion chamber temperature for gasoline engines is between 500°C–850°C. Within that range it is cool enough to avoid pre-ignition and plug tip overheating (which can cause engine damage), while still hot enough to burn off combustion deposits that cause fouling.

An unaltered engine will run within the optimum operating range straight from the manufacturer, but if you make modifications such as adding a turbo or supercharger, increasing compression, timing changes, use of alternate fuels, or sustained use of nitrous oxide, these can alter the plug tip temperature, necessitating a colder plug.

A good rule of thumb: use one heat range colder for every 75–100hp added.

In identical spark plug types, the difference from one full heat range to the next is the ability to remove 70°C to 100°C from the combustion chamber.

Causes of Overheating

The most serious result of selecting a heat range that is too hot is overheating. Overheating will cause the electrodes to wear quickly and can lead to pre-ignition. Pre-ignition occurs when the air-fuel mixture is ignited by a hot object/area in the combustion chamber before the timed spark event occurs. When the spark plug firing end (tip) temperature exceeds 800°C, pre-ignition originating from the overheated insulator ceramic can occur. Pre-ignition will dramatically raise the cylinder temperature and pressure and can cause serious and expensive engine damage. When inspecting a spark plug that has experienced overheating or pre-ignition, blistering on the ceramic insulator and/or melted electrodes can sometimes be found.- Spark plug heat range too hot

- Insufficient tightening torque and/or no gasket

- Over-advanced ignition timing

- Fuel octane rating too low (knock is present)

- Excessively lean air-fuel mixture

- Excessive combustion chamber deposits

- Continuous driving under excessively heavy load

- Insufficient engine cooling or lubrication

As a general guideline, among identical spark plug types, the difference in tip temperature from one heat range to the next is approximately 70°C to 100°C.

Some factors to consider in selecting the proper heat range spark plug

There are many external influences that can affect the operating temperature of a spark plug. The following is a brief list to consider in avoiding reduced performance and/or expensive engine damage.

Engine Speed and Load - If the engine is to be operated at high RPM, under a heavy load, or at high temperatures for long periods a colder heat range may be needed.

- Conversely, if the engine is to be operated at low speeds or at low temperatures for long periods, a hotter heat range might be needed to prevent fouling.

Air-Fuel Mixture - Excessively rich air-fuel mixtures can cause the plug tip temperatures to decrease and carbon deposits to accumulate, possibly causing fouling and misfires.

- Excessively lean air-fuel mixtures can cause the cylinder and plug temperatures to increase, possibly resulting in knock and/or pre-ignition. This may cause damage to the spark plug and/or seriously damage the engine.

- If an air-fuel ratio meter or gas analyzer is not available, it will be necessary to visually inspect the spark plugs frequently during the tuning process to determine the proper air-fuel mixture.

Fuel Type / Quality - Low quality and/or low octane fuel can cause knock which will elevate cylinder temperatures. The increased cylinder temperature will cause the temperature of the combustion chamber components (spark plug, valves, piston, etc.) to rise, and will lead to pre-ignition if the knock is uncontrolled.

- When using an ethanol blend fuel with high ethanol content in high performance applications, a colder heat range may be necessary. The spark timing can be advanced further because ethanol blend fuel has a higher resistance to knock (higher octane). Due to the decreased knock, there will be less audible “warning” from knock before the spark plug overheats and pre-ignites.

- Some types of fuel additives in lower quality fuels can cause spark plug deposits that can lead to misfires, pre-ignition, etc.

Ignition Timing - Advancing ignition timing by 10° will cause the spark plug tip temperature to increase by approximately 70° to 100°C.

- A colder heat range spark plug may be necessary if the ignition timing has been advanced to near the knock level. Higher cylinder temperatures near the knock level will bring the spark plug firing end temperature closer to the pre-ignition range.

Compression Ratio - Significantly increasing the static/dynamic compression ratio will increase cylinder pressures and the octane requirement of the engine. Knock may occur more easily. If the engine is operated near the knock level, a colder heat range spark plug may be necessary due to the resulting increased cylinder temperatures.

Forced Induction (Turbocharging, Supercharging) - A colder heat range spark plug may be necessary due to the increased cylinder temperature as boost pressure (manifold pressure) and subsequent cylinder pressure and temperature increase.

Ambient Air Temperature / Humidity - As the air temperature or humidity decreases, the air density increases, requiring a richer air-fuel mixture. If the air-fuel mixture is not properly richened, and the mixture is too lean, higher cylinder pressures / temperatures, knocking, and the subsequent increase in the spark plug tip temperatures can result.

- As the air temperature or humidity increases, the air density decreases, requiring a leaner air-fuel mixture. If the air-fuel mixture is too rich, decreased performance and/or carbon fouling can result.

Barometric Pressure / Altitude - Air (atmospheric) pressure and cylinder pressure decrease as altitude increases. As a result, spark plug tip temperature will also decrease.

- Fouling can occur more easily if the air-fuel mixture is not adjusted to compensate for the altitude. Higher altitude = less air = less fuel

Changes in Voltage Requirements

The voltage that is needed to create the proper flame kernel at the spark plug’s electrodes varies based on a number of factors, some related to the spark plug itself and others to engine operating conditions.

Causes of Carbon Fouling

Carbon fouling occurs when the spark plug firing end does not reach the self-cleaning temperature of approximately 450°C (842°F). Carbon deposits will begin to burn off from the insulator nose when the self-cleaning temperature is reached. When the heat range is too cold for the engine speed, the firing end temperature will stay below 450°C and carbon deposits will accumulate on the insulator nose. This is called carbon fouling. When enough carbon accumulates, the spark will travel the path of least resistance over the insulator nose to the metal shell instead of jumping across the gap. This usually results in a misfire and further fouling.

Some causes of carbon fouling include:- Continuous low speed driving and/or short trips

- Spark plug heat range too cold

- Air-fuel mixture too rich

- Reduced compression and oil usage due to worn piston rings / cylinder walls

- Over-retarded ignition timing

- Ignition system deterioration

- Pre-delivery fouling

If the selected spark plug heat range is too cold, the spark plug may begin to foul when the engine speed is low or when operating in cold conditions with rich air-fuel mixtures. In some cases, the insulator nose can usually be cleaned by operating the engine at higher speeds in order to reach the self-cleaning temperature. If the spark plug has completely fouled, and the engine will not operate correctly, the spark plug may need to be cleaned / replaced and the fouling cause identified.

Types of Abnormal Combustion

Pre-ignition- Pre-ignition occurs when the air-fuel mixture is ignited by a hot object / area in the combustion chamber before the timed spark event occurs.

- When the spark plug firing end (tip) temperature exceeds 800°C, pre-ignition originating from the overheated insulator ceramic can occur.

- Is most often caused by the wrong (too hot) heat range spark plug, and/or over-advanced ignition timing. An improperly installed (insufficient torque) spark plug can also result in pre-ignition due to inadequate heat transfer.

- Pre-ignition will dramatically raise the cylinder temperature and pressure and can melt and hole pistons, burn valves, etc.

Knock- Occurs when part of the air-fuel mixture in the combustion chamber away from the spark plug is spontaneously ignited by the pressure from a flame front originating from the spark plug. The two colliding flame fronts contribute to the “knocking” sound.

- Knock occurs more frequently when using low octane fuel. Low octane fuel has a low resistance to knock (low resistance to ignition)

- Knock is related to ignition timing. (Knock is sometimes referred to as “Spark-knock”.) Retarding the ignition timing will reduce knock.

- Heavy knock often leads to pre-ignition.

- Heavy knock can cause breakage and/or erosion of combustion chamber components.

- Knock is sometimes referred to as “ping” or “detonation”.

Misfires

A misfire occurs when the spark travels the path of least resistance instead of jumping across the gap. Misfires can be caused by the following:- Carbon fouling

- Worn or deteriorated ignition system components

- Too large of gap size

- Spark timing excessively advanced or retarded

- Damaged spark plugs (cracked insulator, melted electrodes, etc)

- Mismatched ignition system components (plug resistance / wire resistance, ignition coils / igniter modules, etc.)

- Insufficient coil primary and/or secondary voltage – voltage required to jump the spark plug gap higher than coil output

Indexing of spark plug

A matter of some debate is the "indexing" of plugs upon installation, usually only for high performance or racing applications; this involves installing them so that the open area of the spark gap, not shrouded by the ground electrode, faces the center of the combustion chamber, towards the intake valve, rather than the wall. Some engine tuners believe that this will maximize the exposure of the fuel-air mixture to the spark, also ensuring that every combustion chamber is even in layout and therefore resulting in better ignition; however, others believe this is useful only to keep the ground electrode out of the way of the piston in ultra-high-compression engines if clearance is insufficient.

In any event, this is accomplished by marking the location of the gap on the outside of the plug, installing it, and noting the direction in which the mark faces; then the plug is removed and additional washers are added to change the orientation of the tightened plug. This must be done individually for each plug, as the orientation of the gap with respect to the threads of the shell is random. Some plugs are made with a non-random orientation of the gap and are usually marked as such by a suffix to the model number; typically these are specified by manufacturers of very small engines where the spark plug tip and electrodes form a significantly large part of the shape of the combustion chamber. The Honda Insight has indexed spark plugs from factory, with four different part numbers available corresponding to the different degrees of indexing to achieve most efficient combustion and maximum fuel efficiency.

Installing Spark Plugs Without A Torque Wrench

Decoding the NGK Spark Plug

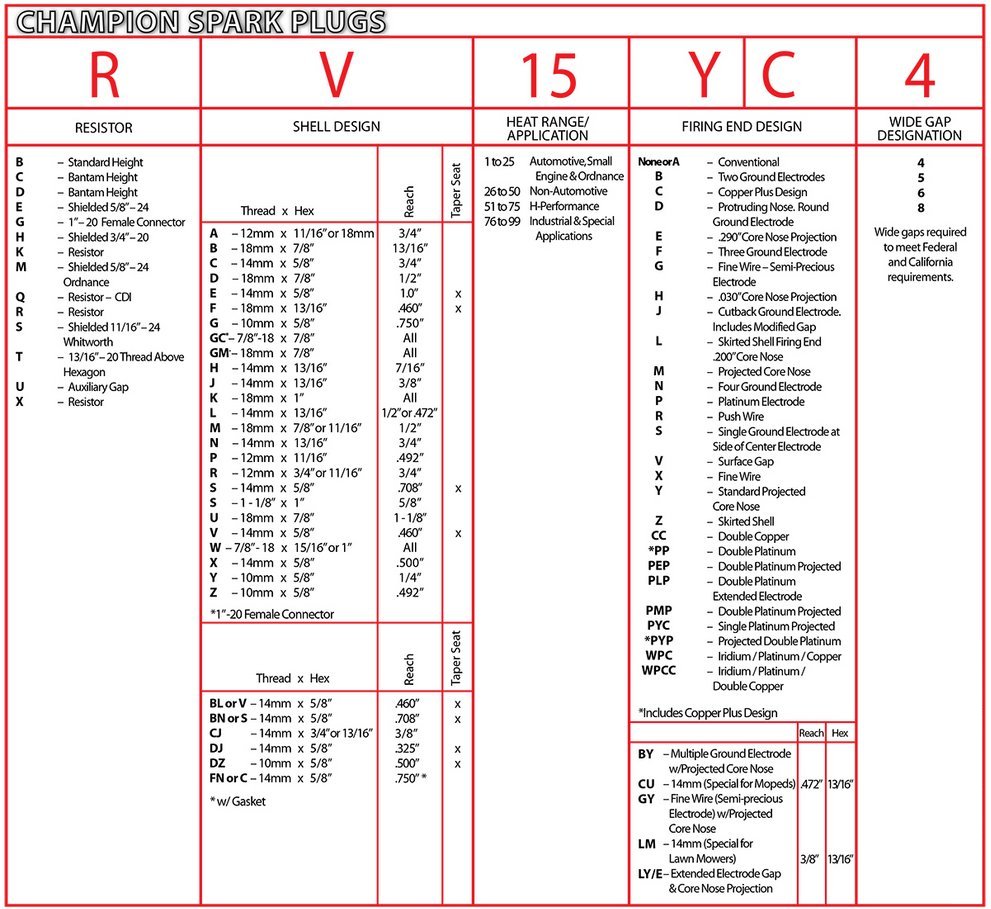

Decoding the Champion Spark Plug

Spark Plug Heat Range Cross Reference Chart

<credits>

Some of the information in this post was obtained from sources such as:

wiki

NGK

Champion

Sparkplugs.com

|

|