|

Turbo Dodge IntermediateShaft

CV Axle Seperation

So you want or need to remove the CV axle from the passenger side intermediate shaft on your 1984-1993 turbo Dodge?

There are few things more for certain in life than knowing that if you can not pretty easily slip the CV joint axle out of the receiver portion of the turbo Dodge equal length intermediate shaft it is going to be almost impossible to force it out with dead blow hammers, heat and other extreme measures! This is one of those service procedures that it pays to know one of the tricks of the trade and to use your frontal lobe rather than your brawn and muscle.

PROBLEM PROBLEM

If the CV axle has been subjected to moisture, road salt and was not coated with a grease or a never-seize type of product, the splines of the CV axle seem destined to become one with the splines of the receiver in the intermediate shaft end. Due to the construction of the intermediate shaft bearing and its dust and gravel slinger it is not easy to get any hammer or dead blow tool in to force them apart and even if you could, that approach typically winds up damaging the bearing slinger or possibly the CV axle tulip housing. It’s just not a good idea to bang on it as if it were an indestructible housing made of titanium infused with kryptonite!. Yes, even Superman would have difficulty with this task.

SOLUTION SOLUTION

Apply the force of hydraulic pressure. Hydraulic pressure has been used for centuries to apply force that man, hammer, vice or machines can not. The method described here is actually quite simple, inexpensive, quick and easy.

|

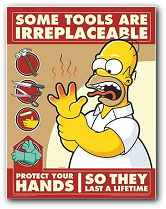

SAFETY FIRST

|

|

This process involves creating quite a bit of hydraulic force inside the intermediate shaft tube with a hydraulic grease gun. You need to wear some protective eye wear and guard your body from possible harm during this process. You do not want to be standing in the path of any flying objects that are traveling under the speed created by the sudden release of hydraulic pressure. Be aware that as the axle starts to move out of the shaft receiver, there is a lot of trapped pressure and it wants to get out! This process involves creating quite a bit of hydraulic force inside the intermediate shaft tube with a hydraulic grease gun. You need to wear some protective eye wear and guard your body from possible harm during this process. You do not want to be standing in the path of any flying objects that are traveling under the speed created by the sudden release of hydraulic pressure. Be aware that as the axle starts to move out of the shaft receiver, there is a lot of trapped pressure and it wants to get out!

THE STUCK AXLE COULD RELEASE SUDDENLY UNDER HIGH PRESSURE AND ROCKET ALL THE WAY OUT AND ACROSS YOUR WORK SHOP! DON’T BE STANDING IN THE PATH OF PARTS THAT LAUNCH UNEXPECTEDLY!

The pressure will lower as the axle begins to move out and as you apply additional pumps from the grease gun the pressure will build again and lower again as the axle moves out. Use some caution and some common sense.

|

|

Here is what is needed:

- Drill bit for zerk fitting

If you are using 1/4” zerk fitting the #3 drill bit is .213” or 5.41mm or about 7/32” (.218”)

(see chart 1 below or visit https://www.aetnascrew.com/lubrication-grease-fittings.html for more information)

- Zerk fitting, 1/4 thread type will be sufficient

- Teflon tape

- Grease gun

- Grease (tube style)

- Penetrating oil

- Shop towels or rags

ZERK FITTING CHART 1

Here Is The Simple Method

Place your equal length axle and shaft assembly on your bench. Be careful to not damage the machined surfaces. You are going to need some shop towels to wipe up the mess you are likely to make.

- Drill a hole into the intermediate shaft tube on the yoke end nearest the U-joint for a zerk fitting.

- Tap the hole for a zerk fitting

- Teflon tape the threads of the zerk fitting

- Install the zerk fitting

- Spray some penetrating oil into the tube so that it might reach the end of the axle shaft inside the tube

- Pump in some grease. Using a pump style bearing and joint grease gun you simply pump in the amount of grease needed to cause the CV axle to be pushed out of the receiver end of the shaft. The amount of grease required will vary however, the inside capacity of the intermediate shaft tube seems to be about 3-6oz.

- The axle might not want to come out of it’s comfortable home. If after you apply 3+oz of grease the axle does not begin to start moving out, let the penetrating oil and the pressure do its work. Let the piece sit for several hours under pressure. It’s the pressure that is going to do the heavy lifting here. The pressure can easily reach hundreds or thousands of pounds of force and it’s important to remember that. No need to try to go too fast, let the pressure and oil do it’s thing.

- Remove the grease. After the axle has been removed, it’s a good practice to remove the grease from the inside of the tube. You can do this with carb and choke or brake parts cleaner and perhaps a tooth brush to speed it up the process a bit..

PLEASE NOTE: There is a fiber/rubber weather seal that should be present between the axle and the intermediate tube receiver. It is important to have that rubber seal in place when you reassemble. It is there to prevent moisture from entering the spline area. See the picture below for better understanding if necessary.

The End Result!

CV Axle Weather Seal

|