|

NOTE: It is very important to note that the installation of any device that allows you to run additional boost, beyond the factory computer controled settings, carries with it a degree of risk of catestrophic engine damage! When you install this type of device it is absolutely necessary for the safety of your engine, to start out by insuring that your vacuum and boost control harness and all vacuum lines are in good working order and can handle the additional boost levels. You also need to start at a boost setting that will retain the factory boost level and then gradually turn up the boost to a maximum of 14psi (2 bar) setups. Even further, we suggest that you slowly turn up the boost from the factory setting to perhaps 10psi or 12psi and then get accustomed to the new power before (or if you choose) you turn it up to a maximum setting. This also allows you to verify that your vacuum and boost control harness is up to the task of handling the higher boost levels. We can not stress the importance of these precautions enough.

|

|

|

The installation of a “Grainger Valve” in your turbo Dodge automobile should only take a few minutes and is very straight forward. Only simple hand tools will be required.

Step 1: Locate the rubber boost line that connects the intake manifold to the nipple on the side of the waste gate acctuator.

Step 2: Find a spot in that line that will be convenient to access when the Grainger valve has been installed. To tune for additional boost, you will be required to loosen the jam nut on the valve and give it 1/2 to 1 full turn and then retighten the jam nut so the ability to access the valve conveniently is important.

Step 3: Cut the rubber line that goes from the intake manifold to the wastegate actuator in the sport you chose in step 2.

Step 4: Loosen the jam nut on the Grainger valve and turn the valve to make it longer. Blow with force into the nipple of the straight end of the valve and continue to make the valve longer till you can blow through the valve. Once you can cause the valve to open with your own breath, turn the valve approximately two (2) turns to make it shorter. This will be your initial setting and SHOULD allow the valve to open at the factory computer controled boost setting. Snug the jam nut in place.

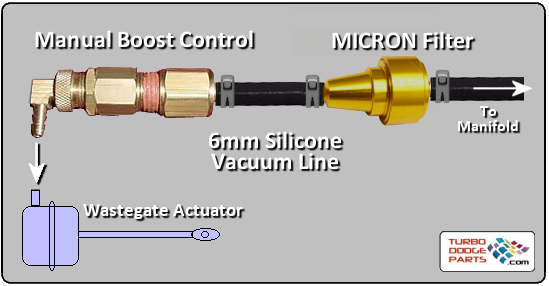

Step 5: Insert the Grainger valve and it’s filtration system in the rubber line as shown in the illustration below. Proper orientation of the valve is of course critical. Installing the valve backwards will cause the valve to malfunction and you will loose all boost control and possibly create an over-boost condition which could possibly result in a catestrophic engine failure.

|

Step 6: Drive the car. At first do not go immediately to boost. Take it easy and see what boost setting you are running at. You should be still at the factory boost setting. If you are getting more than 10-12psi, immediately GET OFF THE GAS! If you are getting more than 10-12PSI at first, open the valve to make it longer 1 full turn and road test again. Continue this process till the boost level is at 10-12psi.

If the boost is at factory level, then adjust the valve one full turn to make it shorter and road test again. Continue this process till you start to see an increase in max boost pressure. When your setting allows you to reach 10-12 psi, then set the jam nut and we suggest that you drive the car a bit to get use to this new amount of boost and added power.

Once you have driven the car a bit and gotten use to the new power levels and are confident that your vacuum line system can handle the added boost pressure, you might want to continue to turn up the boost, 1/2 turn at a time at the valve (to make it shorter) till you reach a boost level of your liking but less than or equal to approximately 14psi.

DO NOT GO OVER 14 PSI unless you have a system or custom calibration that is going to add additional fuel while under higher boost levels or you will have a catestrophic engine failure. This is pretty much guaranteed. Running the engine lean under high boost creates massive amounts of heat in the combustion chamber and if there is any engine detonation you will either gaul a piston or bust one(or more)!

|