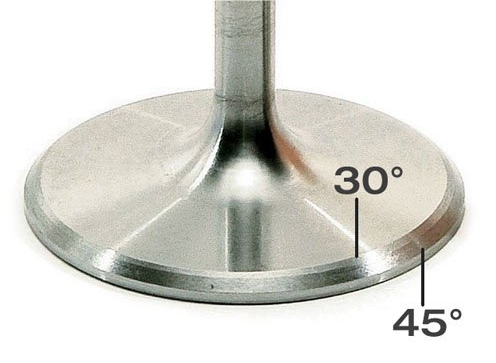

After the valves have been lapped, a backcut is placed on the back of the valve, close up to the inner edge of the 45° seating area. This further improves flow around the head of the valve. After the valves have been lapped, a backcut is placed on the back of the valve, close up to the inner edge of the 45° seating area. This further improves flow around the head of the valve.

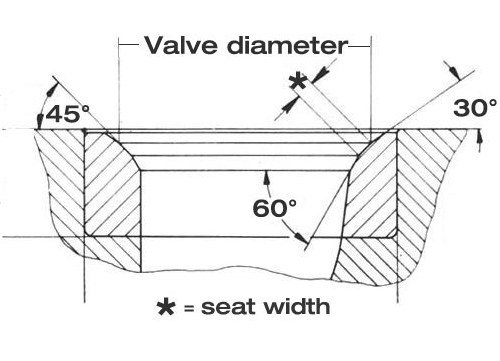

On the inlet valve, the lap marks should be placed on the outer edge of the 45° valve face. This takes full advantage of the diameter of the valve. When the lap marks sit inside the outer edge of the valve, the overhanging portion of the valve serves as an obstruction to flow. The top cut on the seat (usually 30 degrees), establishes the outer edge of the seat and helps turn flow into the combustion chamber. A 60 degree bottom cut sets the width of the 45°seat.

The 45° exhaust seat is deliberately kept inboard of the outer edge of the valve - otherwise hot exhaust gas will eventually erode the edge of the valve.

Look at a

typical stock replacement cylinder head and you'll find they have a basic 45° angle cut on to the seat. On these heads, you can lap in the valves and inspect the valve face to see exactly where the seat is coming in contact with the valve face. Even on aftermarket heads that come out of the box with a three angle cut, when you lap in the valves you'll often see the angles haven't been placed for optimum performance.

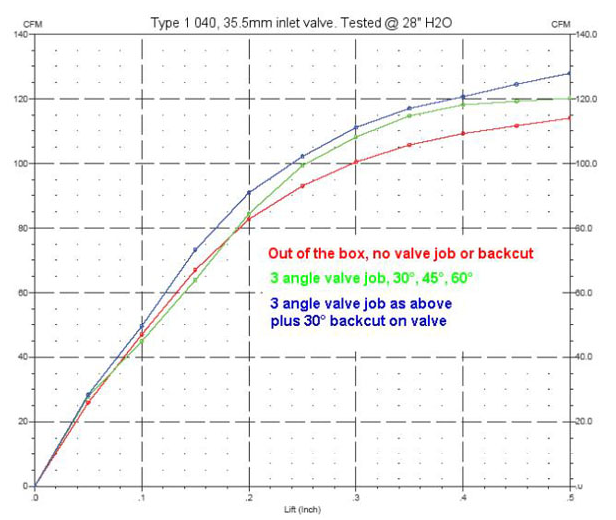

The graph below shows the results of a typical flow test carried out on a brand new CNC 044 cylinder head (40mm inlet valve).

- The red line shows 'out of the box' flow with the factory fresh 3 angle seat.

- The green line shows the improvement by recutting and repositioning the 45° cut to the outer edge of the valve.

- The blue line indicates flow when a 30° back cut to the valve was added.

- Red line: straight out of the box with no mods

- Green line: 3 angle valve job

- Blue line: 3 angle valve job plus 30° backcut on the valve

OVERALL GAIN IN FLOW @ .500" lift: 14cfm

This illustrates how even the mildest of engine builds will benefit from the addition of a decent valve job. On a mild 4 cylinder engine build, such as a Chrysler 2.2 OR 2.5 liter engine, this modification alone could account for an increase of 10bhp or even more on turbocharged engines.

This is not an expensive upgrade to a standard 3 angle performance valve job and most machine shops are happy to add this additional option for less than $50 on a 8 valve cylinder head, maybe even on a 16, just depends on the pricing at your local machine shop.

|