|

This tech tip/FAQ reveals the correct piston to cylinder wall clearance required for installing a set of Wiseco forged pistons in your turbo Dodge engine. Forged pistons require a totally different clearance profile than cast pistons and getting it right the first is very important. As they warm up, a forged piston will swell in diameter more than a cast piston and therefore the clearances will be different.

Wiseco technical support and the documentation shipped with the pistons indicate you need a clearance of .0035”. If you are running above 15psi boost, and as high as 30psi add another .001 to it.

|

General Information

Forging #: F6095XA2

Comp Height: 1.596

Bore Size: 3.4640

Suggested Clearance: 0.0035”

|

Piston diameter should be measured at the lowest point of the piston skirt or 1.300” from bottom of oil ring as shown below.

|

|

Piston Pins / Retainer Clips

|

Rings

|

|

Piston Pin #: S611

Diameter: .901

Length: 2.500

Retainer Clip #: W5860

Width or Wire Dia: .0720

|

Top Ring

Second Ring

Third Ring

|

Thick

.3600

.2000

.1000

|

Grv Wdth

.0410

.0490

.1113

|

Grv Root Dia

3.159

3.1210

3.1530

|

|

|

Dome and Valve Pockets

|

|

Dome Rise: -.175

Dome Volume: -15.0

Deck Thickness: .425

|

|

Pocket Dia

Angle

Depth from TE

|

Intake

1.7000

7.50

-.0960

|

Exhaust

1.7000

7.50

-.0960

|

|

Specifications and Installation Instructions for

Wiseco Automotive Pistons

Piston to Cylinder Wall Clearance - Wiseco pistons are machined with a special cam and barrel design. When measuring for piston to wall clearance, measure at widest point of piston skirt 1.300” from the bottom of the oil ring groove, 90 degrees from piston pin hole.

Valve to Piston Clearance - Most Wiseco pistons are machined with valve pockets that are deeper and larger than stock. These pockets provide adequate valve clearance under most conditions. It is very important that valve to piston clearance be checked upon piston installation. This is necessary due to many variations in cams, how much a block has been decked or if the head(s) have been cut or angle milled.

CAUTION: Use only Wiseco spiro Lox retainer clips in pistons manufactured for Spiro Lox clips and round retainer wire clips for pistons manufactured for round retainer wire clips. Use only Wiseco part number retainer clips in Wiseco pistons. Substitution can result in severe engine damage. Wiseco also recommends that retainer clips are not reused.

Check for Proper Ring End Gap

Failure to ensure proper ring end gap may cause ring tips to butt, and engine damage is very likely to occur.

- A torque plate should be attached to the engine block or cylinder (if applicable) and torqued to specifications

- Check the end gap by placing the ring into the cylinder. Cylinder bore should be free from taper. Use the piston to square up the ring in the cylinder bore, and check the ring end gap by using a feeler gage.

- See the table below for the proper ring end gap for your application

- The oil rails may be installed without modifying the end gap. The gap should be a minimum of 0.010”

Ring Gap Table Instructions

- This table is in inches. If you are measuring your bore in millimeters, you will need to convert to inches by dividing your bore size by 25.4

- Multiply your inch bore size by the “Bore X” column for your application to determine the end gap.

Example: For the top ring on an ATV with a 4.0” bore, multiply 4.0 x .004 = .016

|

Notes

- The chart to the right is a general guideline. Each ring should be fitted to the particular cylinder in which they are to be installed

- The gap on the second ring should always be larger than the top ring end gap, this will help to reduce top ring flutter or lifting

|

Application

|

Top Ring

Bore x

|

2nd Ring

Bore x

|

|

Dirt, ATV, Snow, PWC

|

.0040”

|

.0050”

|

|

High Performance Street/Strip

|

.0045”

|

.0055”

|

|

Street Moderate turbo/Nitrous

|

.0050”

|

.0055”

|

|

Late Model Stock

|

.0050”

|

.0055”

|

|

Circle Track/Drag Race

|

.0055”

|

.0060”

|

|

Blown Race Only

|

.0065”

|

.0070”

|

|

Nitrous Race Only

|

.0070”

|

.0075”

|

|

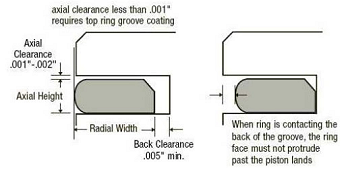

Ring Installation

Check each ring in it’s corresponding piston ring groove to insure proper axial and radial clearance. Check each ring in it’s corresponding piston ring groove to insure proper axial and radial clearance.

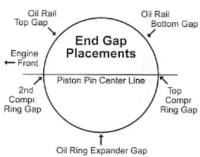

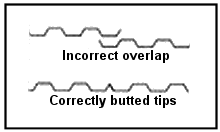

- Oil Ring Expander: Place the oil ring expander into the oil groove with the butted tips of the expander 90 degrees from either end of the wrist pin. Be sure the tips of the expander are visable and properly butted, not overlapping. If the oil expander tips are overlapped, the engine will smoke due to excessive oil use and engine damage could occur.

- Oil Rails: The oil rails can be installed with either side up. Using a ring expander, install

the rails into the oil groove, placing the first rail below the expander, and the second rail above the expander. The rail end gaps should be located at least 90 degrees from each other. After the rails are installed, double check that the tips of the expander are still properly butted and not overlapped. the rails into the oil groove, placing the first rail below the expander, and the second rail above the expander. The rail end gaps should be located at least 90 degrees from each other. After the rails are installed, double check that the tips of the expander are still properly butted and not overlapped.

- Second Ring: Using a piston ring expander, install the second ring with the marked side up. If the ring is not marked on one side near the end gap, AND does not have a bevel, either side can be up. An unmarked 2nd ring, with an inner bevel, should be installed bevel side down (See illustration 4)

Top Ring: Using a piston ring expander, install the top ring with the marked side up. If the ring is not marked on one side near the end gap, AND does not have a bevel, either side can be up. An unmarked top ring, with an inner bevel, should be installed bevel side down (See illustration 5) Top Ring: Using a piston ring expander, install the top ring with the marked side up. If the ring is not marked on one side near the end gap, AND does not have a bevel, either side can be up. An unmarked top ring, with an inner bevel, should be installed bevel side down (See illustration 5)

Filing Gaps

- Wiseco recommends filing ring end gaps using the proper ring end gap filing tool, either an electric ring grinding machine or manual hand crank style grinder. (See Illustrations 1 & 2)

- Always file from the ring face towards the inside diameter to avoid damaging the face coating. (See Illustration 3)

- File only one end of the ring. Use the un-filed end as a reference.

- Be sure to keep end gaps square. (See illustration 4)

- File until the desired end gap is achieved.

- Remove all sharp edges and burrs. Note: Failure to remove all burrs and sharp edges could cause engine damage.

|

If you are looking for a set of Wiseco pistons for your turbo Dodge, you can contact TurbosUnleashed(.com), they are an authorized reseller of custom Wiseco forged pistons for your 2.2 and 2.5 turbo Dodge applications.

|

|

|