TURBO DODGE WIPER BUSHING AND PIVOT REPAIR/REPLACEMENT

When recently reworking and repairing the wiper arm bushings on my 86 Omni L-body car I noticed something that was probably the root cause of one of the transmission arms popping off to begin with.

I noticed that the pivot assembly that the windshield wiper arm attaches to was pretty stiff and not that easy to turn. After disconnecting the other wiper arm, I also noticed that it was even harder to move. And I don't mean a little stiff, it was very hard to make it move back and forth.

Apparently over time, these pivots get stiff and that is not only going to make the motor work harder but also cause the bushings to have to withstand additional force to move the arms and I speculate that the wipers are going to be much more prone to chatter. All this extra torque and force is probably what causes the bushings to fail prematurely. I think they do also fail from wear and perhaps the wear comes from them not being permanently well lubricated. But at least in this case, I think my root cause was the pivots both being darn hard to turn.

To fix them, I simply removed them from the car, making note that there is a (R) and a (L) side, the left one having a longer arm. Then soaking them in penetrating oil, first with CRC Freeze Off (which I love!) and then with a bit of PB Blaster and exercising the little arms round and round till they were very easy to turn again. Then a few drops of 3M oil.

Just in case you need the numbers for the bushings:

HELP! part number is: 49447 (arm bushing) 2 REQUIRED

DORMAN part number is: 49439 (motor/crank bushing)

These numbers were from the AutoZone catalog however I checked O'Riley, Advance Auto Parts, and Amazon and they all list it under the same number.

NOTE: The crank bushing is not that easy to change. It takes a bit of effort and you have to be very careful to make note of the exact position of the crank before you remove it! Get it wrong and the arm timing will be off. You should mark the parts well before you take it apart to change the crank bushing.

You can also disassemble the pivot assembly and lubricate the pivot shaft after giving it a little clean-up.

Completely eliminated the blade chatter that wouldn't stop, and now the speed of the wipers is correct because the motor is no longer laboring to push the arms around.

I'm happy, it's good. Here are some pics of the pivot disassembled. I used a simple punch to press the arm off the pivot shaft, cleaned the shaft with a wire wheel, lubed with some synthetic wheel bearing grease and reassembled.

Here are two helpful tips:

- Heat the bushings in boiling water before you try to install them in the arms. If they are softer, they snap in place easier.

- When you lubricate the pin that goes into the bushing, don't over fill the bushing or it will be really hard to get the pin to insert because the excess grease will not have anywhere to go as you compress the pin into the bushing. Put a very little bit of grease in the bushing and use some small tool to swirl the grease up against the inner walls of the bushing. Then lube the pin, get the grease in the pins locking grove.

To get the pin to go inside the bushing I use a pair of channel lock pliers or my bench vice. Just a little bit of pressure, applied for a few seconds will get the pin to slip into place and get the locking groove into position. You have to go slow because if you put in just a little too much grease, it has to leak its way past the bushing seal before the pin can be fully inserted.

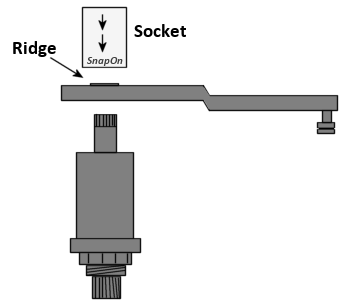

To get the bushing into the arm, the best trick I have found is to first lube the lip of the bushing with a little grease, I use silicone. Then place the cap (closed end)of the bushing on a solid surface, then a socket on top of the bushing on the other side. Choose a socket just a little larger than the bushing hole in the arm and large enough to clear the lock on the side of the bushing. Then one good tap with a mallet on the socket will push the bushing into the arm hole. You can not push the bushing into the arm with your hands.

- Not too much grease

- Use a channel lock plier and a few seconds of pressure, a vice also works good. Apply the pressure slowly to avoid rupturing the bushing

- Don't hammer on the pin to try to get it into the bushing, the bushing will rupture if too much grease was applied and you try to force it in

- Use a socket and a good tap with a hammer/mallet to get the bushing into the arm.

|

Question:

After you press or punch out the pivot shaft from the arm, how do you reattach? It seems like it should be staked or tack welded or something otherwise it seems like it would/could come off easily.

|

|

It is a press fit to begin with. When I removed mine I was careful to properly support the arm and leave the body of the pivot hanging inside the vice jaws, this was so I could drift out the center pin with just a few taps, right down the center...and drift it out w/o cocking the arm or body against each other. The arm and shaft are both ridged/toothed and not indexed so I dont think the arm slipping is so much an issue. Upon reassembly the fit was still good and tight, so like you I am hoping that it will not come apart. But it is still very good fit.

I did however give the end of the pin a pretty good tap or two to mushroom the end for an even tighter fit. It's not staked to begin with but you raise a good point.

I'm not sure if I mentioned it earlier in previous post or not but when I put the arm back on, I placed a socket over the end of the arm and was tapping on the socket to get the pin back into the hole in the arm. The other end of the pin was against the anvil portion of my vice. The grooved wiper arm cap is also a pres fit on the pin but it is staked. I used the socket to press the arm back on to avoid mushrooming the ridge around the outside of the pin hole that is already on the arm. I was concerned that if I ruined/hammered down the ridge, the pin might not go in as far as it did when assembled at the factory. Instead of hammering the arm back on, it could just as easily been pressed back on in the jaws of my vice but again I would have used the socket to avoid deforming the ridge and preventing the pin from going all the way in.

|

Here are some pictures of the placement and location of the wiper bushings. It’s best to do one arm at a time and to make careful note of which end is attached to which pin and which side of the arm faces in or out.

The center pivot bushing is not as easy to replace! In a process similar to servicing the wiper pivot assemblies, you have to first mark the position of the arm to the lever shaft so that you can reassemble the pieces in exactly the same positions, use a drift or punch to remove the pin arm from the lever arm that bolts to the wiper motor, install the new bushing, and then press the pin arm back onto the lever.

|