|

Have you ever wondered how it is that something so simple as a windshield washer nozzle could be so prone to clogging and why it is that you typically can not just stick a wire or needle into it and unclog it?

Maybe you noticed that when you try to blow through one, it always seems to be totally clogged?

It’s all because of a spring loaded 1-way valve that is inside the nozzle housing!

The purpose of the valve is to maintain fluid in the line all the way up to the nozzle jet when it is not in use. Without the 1-way valve, the fluid would leak back down the supply hose to the reservoir and the pump would have to pump the line full again to produce a spray to the glass. This delay would cause the first or maybe even the second wipe of the glass to always be dry. That can scratch the glass as well as wear the wiper blade rubber inserts down much more quickly.

The spring in the check valve is pretty strong, so the pump has to actually deliver quite a bit of pressure to not only defeat the spring, but to also deliver a solid, uninterrupted spray pattern to the glass. The spring is why you can’t easily blow through the nozzle! The 1-way valve also blocks your ability to poke a thin wire through the nozzle to clear it from the bottom, and it also prevents you from back flushing it easily. If you put something in the inlet to push the valve open to try to backflush out some clog or dirt, use something like the back end of a drill bit that just fits in the inlet opening. If you use a sharpe instrument to push on the 1-way valve, you will puncture it and basically ruin your nozzle's anti-drain back feature.

Anatomy of the Nozzle

How to Remove the Nozzle

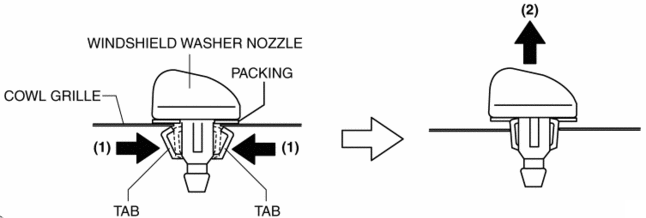

You would think that removing the nozzle from the hood would be a pretty simple task, and it should be...but it’s not! There are a few important things to consider when attempting this nozzle removal.

- The nozzle is plastic, it’s old and it’s probably pretty brittle. If you tug too hard on the hose, you are more than likely going to snap off the inlet barb. It’s surprisingly easy to do. The hose has to have a tight fit to keep from blowing off under pressure.

- The tabs that hold the nozzle in place are also brittle plastic unless the nozzle was recently replaced. To remove the nozzle, I found that it’s best to use a small blade flat screwdriver to push one tab in first and lift up on that side of the nozzle, then push gently on the other tab and lift up the nozzle to remove it. If the nozzle is older you are very likely to break off one or both of the tabs either taking it out or putting it back in.

I have discovered that the Chrysler replacement nozzles are not inexpensive, at least from the perspective of what you get in the bag (two nozzles) for $35! But I also discovered that some of the much less expensive after-market nozzles immediately broke tabs when being installed the very first try. Also, the inlet barb on some of them is quite thin and it was also easy to snap off the barb just trying to get the hose back on it. Remember, the hose has to be a tight fit or it will pop off under pressure. For old hoses I discovered that a small zip tie works great for holding the hose on the barb...just don’t tug on that zip tie too hard!

|