Product Description

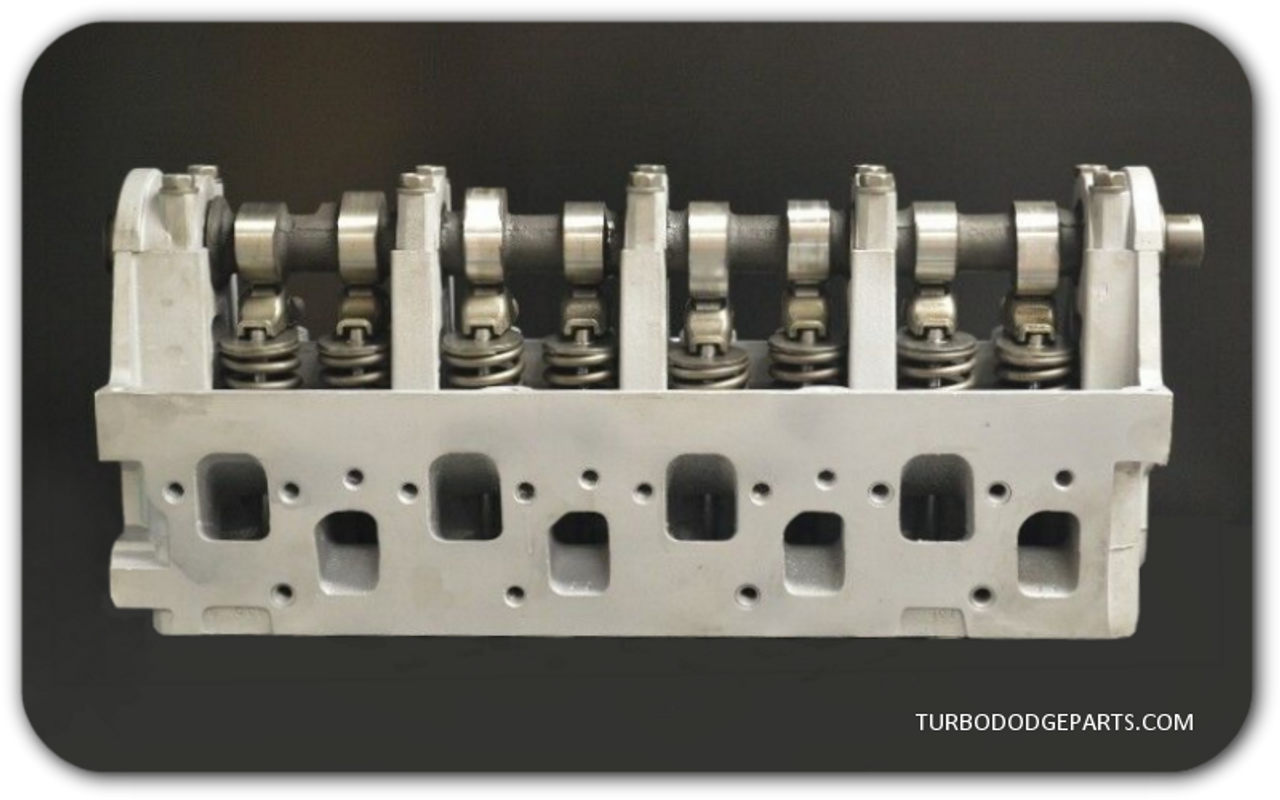

REBUILT STOCK CHRYSLER/TURBO DODGE 2.2/2.5 CYLINDER HEADS

782 “FAST BURN” & "SWIRL" CASTING HEAD

We offer a selection of professionally rebuilt, genuine Chrysler 2.2/2.5 cylinder heads with a complete selection of stock features for use on both normally aspirated and turbo charged engine applications for the Chrysler, Plymouth and Dodge automobiles built from 1983 to 1993 and utilizing the popular 2.2 and 2.5 liter engines.

These guaranteed genuine Chrysler manufactured cylinder heads have been professional machine shop refurbished and completely rebuilt including deep chemical cleaning, pressure tested for leaks and inspected for cracks, block to head surface resurfacing, new valve seats and valve guides with integrated locks as needed , new positive clad valve stem seals and on stock and performance heads a complete 3 angle valve job, assembled height and spring pressures checked and within factory performance specs, stock 88 TBI roller(782) camshaft, roller cam followers. The non-bare heads are delivered completely loaded ready to be installed with all the typical installation accessories, gaskets and needed hardware.

Each “STOCK” upgraded Chrysler 782 2.2/2.5 cylinder head is delivered fully loaded with the following:

- Professional machine shop rebuilt cylinder head

- New valve seats w/ 3 angle valve job

- Back cut intake and exhaust valves for more flow and horsepower(option)

- Stock Size Intake & Exhaust Valves

- Stock Turbo Valve Springs

- Stock Intake/Exhaust Valve Locks/Keepers

- OEM Valve Spring Retainers

- OEM Roller Cam Followers

- New valve guides w/locks as needed

- OEM 88 TBI Cam

- Front and Rear Cam Seals

- Stock Lifters With Shims

- Standard Valve Stem Seals

- Turbo Dodge Parts Ultimate intake bolts*

- Turbo Dodge Parts Ultimate exhaust studs with copper clad flange nuts

- FelPro 11mm head bolts

- FelPro Valve Cover Gasket (1 piece or multi-piece design)

- FelPro PermaTorqe head gasket

- FelPro Intake/Exhaust manifold gasket

- No cylinder head core required

- Full 1 Year Unlimited Mileage Warranty

Options include the following

- Heavy duty intake and exhaust springs (more RPM)

- Conical springs and retainers (more RPM, less frictional HP loss)

- PT Lifter update (more RPM, smoother idle, quieter operation)

* TBI/CARB car intake manifold bolts are not included w/our standard turbo heads. Reuse your original factory hardware, we do not sell the TBI/Carb car manifold bolts.

ADD BACK CUT VALVES TO YOUR OPTIONS FOR MORE FLOW AND HORSEPOWER

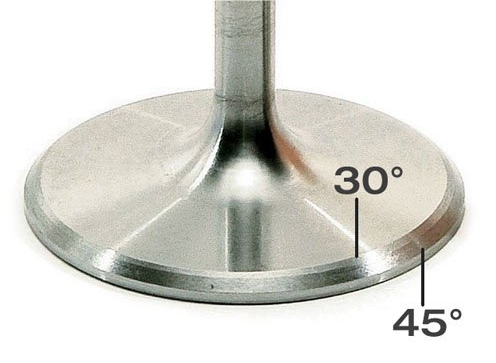

After the valves have been lapped, a backcut is placed on the back of the valve, close up to the inner edge of the 45° seating area. This further improves flow around the head of the valve.

After the valves have been lapped, a backcut is placed on the back of the valve, close up to the inner edge of the 45° seating area. This further improves flow around the head of the valve.

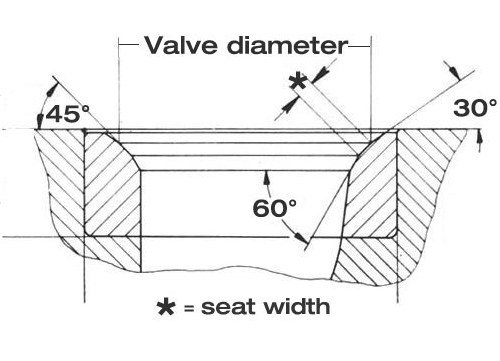

On the inlet valve, the lap marks should be placed on the outer edge of the 45° valve face. This takes full advantage of the diameter of the valve. When the lap marks sit inside the outer edge of the valve, the overhanging portion of the valve serves as an obstruction to flow. The top cut on the seat (usually 30 degrees), establishes the outer edge of the seat and helps turn flow into the combustion chamber. A 60 degree bottom cut sets the width of the 45°seat.

The 45° exhaust seat is deliberately kept inboard of the outer edge of the valve – otherwise hot exhaust gas will eventually erode the edge of the valve.

Look at a typical stock replacement cylinder head and you’ll find they have a basic 45° angle cut on to the seat. On these heads, you can lap in the valves and inspect the valve face to see exactly where the seat is coming in contact with the valve face. Even on aftermarket heads that come out of the box with a three angle cut, when you lap in the valves you’ll often see the angles haven’t been placed for optimum performance.

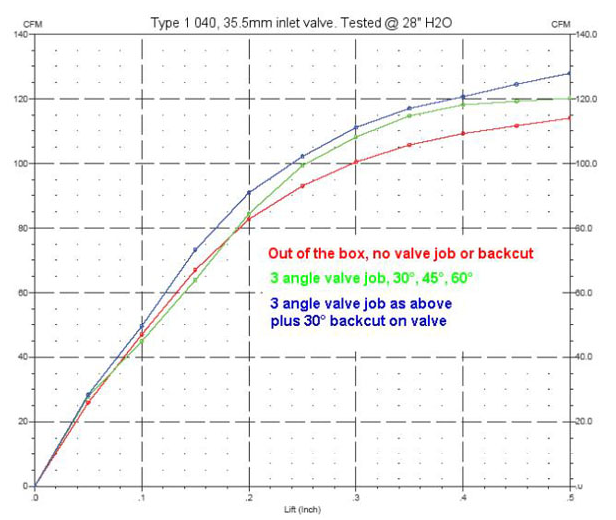

The graph below shows the results of a typical flow test carried out on a brand new CNC 044 cylinder head (40mm inlet valve).

- The red line shows ‘out of the box’ flow with the factory fresh 3 angle seat.

- The green line shows the improvement by recutting and repositioning the 45° cut to the outer edge of the valve.

- The blue line indicates flow when a 30° back cut to the valve was added.

Red line: straight out of the box with no mods

Green line: 3 angle valve job

Blue line: 3 angle valve job plus 30° backcut on the valve

Overall gain in flow @ .500″ lift: 14cfm

This illustrates how even the mildest of engine builds will benefit from the addition of a decent valve job. On a mild 4 cylinder engine build, this modification alone could account for an increase of 10bhp or more.

|

Other Details

One year warrantyProduct Videos

Custom Field

Product Reviews

4 Reviews Hide Reviews Show Reviews

-

782 complete head

Very good product that came complete with bolts and gasket. Would give 5 stars if I could have received it quicker.

-

new head

Car runs great THANKS

-

Awesome work

The head on my 1986 Daytona Turbo Z C/S turned out to be beyond repair, Steven hooked me up with a new one that was from a better casting, it came back looking amazing! My car only had 91,000 miles on it but the cam sliders were very worn out, and it had been cracked and repaired on what looked like several times in the past. I am so glad I got this service done by someone who deals with this particular head all the time. Great work as always!

-

Service Quality

Above any standards Steve is a pleasure to deal with and extremely knowledgeable WELL ABOVE ANY EXPECTATIONS